ZP 29D Automatic Rotary Tablet Press Machine

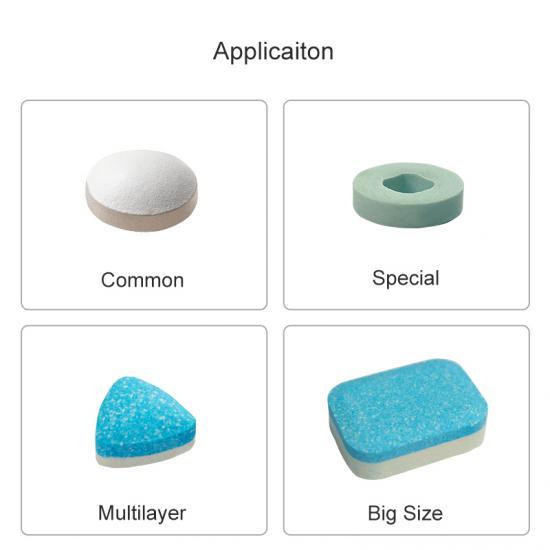

ZP 29D 14 Days Delivery | Guaranteed For 3 Years|Automatic Rotary Tablet Press Machine For Making Kinds of Tablets | Round | Ring | Special | Multicolor | Pharmaceutical Tablet Press | ZP 29D For Industrial Making Tablets | Automatic High Speed Tablet Pressing | Producing ZP 29D Tablet Press Since 1993 | Factory Price | For Tablet Press Into Various Shapes | Provide Door-To-Door Overseas On Site Service |Passed SGS / CE / ISO / cGMP

Rich Packing’s 29D rotary tableting machine is equipped with 29 punches on the middle mold parts of the turntable, and the high capacity provided can reach the output of over 74,800 tablets per hour. This large-purpose machines with two feeders and the two discharge ports are suitable for the selection and the purchase of tablet manufacturers with relatively large scale requirement.

*** Manufacturers with small or tight production factory workshops are just right to choose our this dual-pressure rotary tablet press.

*** With the same space size and the same electric power, our 29D has twice the output of other models. The mass production capacity is suitable for the pharmaceutical, food, chemical and other industries.

*** In order to solve the problems of pressing sticky powder materials, we specially designed the forced feeders. Feeding is no longer solely dependent on the gravity of the powder or pellets itself, but is forced to feed more forcefully and is accurately by forcing the rotary lever in the feeders.

*** Certification: SGS, CE, ISO***

Therefore, easily absorbing moisture and viscous materials are no longer the difficulty of pressing tablets.

If any customers with the similar needs, you can get in touch with we RICH PACKING in time, and we will try our best to provide you with the perfect solutions for viscous materials.

Our company's strength comes from obtaining a huge numbers of national and industry certifications. It has obtained the CE, SGS, ISO9001, and the Guangdong Province Contract and Trustworthy Enterprise Certification. We have over 63 R&D personnel and produces more than 3,000 high-end equipment annually.

Technical parameter

|

Dies No. |

29 set |

|

Max. Production Capacity |

110,000 pcs/h |

|

Max. Pressure |

100KN |

|

Max. Dia. of Tablet |

25mm |

|

Max. Depth of Filling |

24mm |

|

Max. Thickness of Tablet |

12mm |

|

Dia. Of Middle Die |

Ф38.1mm |

|

Length of Upper/Lower Punching Bar |

115mm/133.4mm |

|

Dia.of Upper/Lower Punching Bar |

Ф25.4mm |

|

Rotary Speed |

5~21 r/min |

|

Motor |

5.5kw |

|

Weight of Machine |

1600kg |

|

Outline Dim. |

1040×910×1690mm |

|

Packing Size |

1340×1100×1960mm |

|

Packing size of Dust Collector |

960×620×1460 mm |

*** Configuration List

|

Item |

Specification and Model |

Manufacturer |

|

Overload protector |

Self design |

Self manufacture |

|

Intelligent lubrication system |

American BIJUR DELIMON |

American BIJUR DELIMON |

|

Frequency converter |

VFD037B43B |

Taiwan Delta |

|

AC contactor |

3TB40 22-OXMO |

Germany Siemens |

|

Relay |

MY-2NJ MY-4NJ |

Japan Omron |

|

Upper and lower pressure wheel |

GCr15 |

Self manufacture |

|

Upper rail guide |

GCr15 |

Self manufacture |

|

Turntable |

HT250 |

Self manufacture |

|

Air switch |

DZ108 |

Tengen |

|

Hopper |

1Cr18Ni9Ti |

Self manufacture |

|

Scale hand wheel |

Sensitivity:0.1mm |

Shanghai Lichao |

|

Motor |

Y112M-4 |

Shanghai Lichao |

|

Shell |

S304 |

Thickness 1.5mm |

|

Glass door |

organic glass |

Thickness 15mm |