ZH 260W Automatic Carton Box Packing Machine

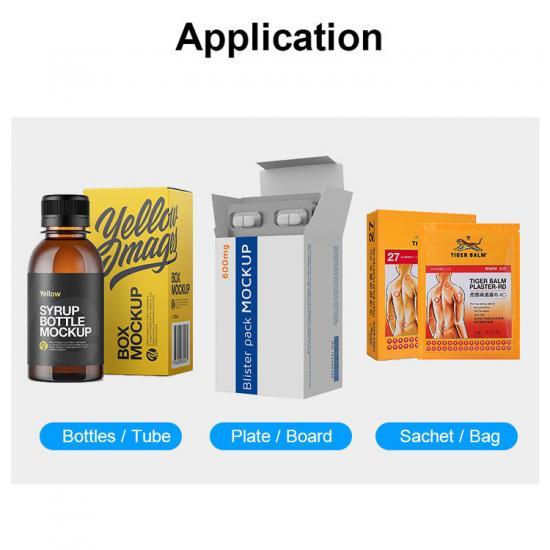

3 Years Warranty | 21 Days Delivery | Our 260W active high-speed carton packing machine is a combination of bottled soft bag like materials and small flat plate like materials, and the application of materials, and then through the process of active and high-speed loading of materials into the folded carton, initially the initiative to complete the carton locking. WeRQ packaging machinery company's 260W ultra-high speed box filling machine has excellent functions.

The working procedure of this 260W automatic cartoning machine can generally be divided into three parts to describe. The three parts of the 260W cartoning machine are the manual adding station, the material adding station and the carton entrance.

The entire running process of 260W from carton feeding to final carton packaging molding is divided into four stages: that is, the carton lowering action, undamaged opening of the carton, correct filling of materials, and accurate folding of the carton.

The action of unloading the box is to suck the carton at the feeding port of the carton through a negative pressure suction cup, and then place the carton on the main line of the cartoning through the positive pressure of the suction cup, and fix the carton on the card position of the fixed motion track. , Jam the sides of the carton from both sides, so that the 260W can open the carton at a right angle and reach the designated filling area.

*** 260W the back pushing of feeding designs. 260W can do better protect the safety of operators.

*** 260W's the parts numbers coded in machine. 260W has do more perfect production and maintenance management ability.

*** the Calibration adjusting handles in 260W. 260W has do more convenient adjustment function.

Technical parameter

| Name | 260W horizental cartoning machine |

|

Production capacity |

260 cartons/min |

|

Net weight of machine |

3450Kg |

|

After warranty service |

video technical support, Online support, Field maintenance and repairing. |

|

Power |

380/220V 50Hz |

|

Total power |

5.05KW |