CAPACITIES: from 200L up to 35.000L.

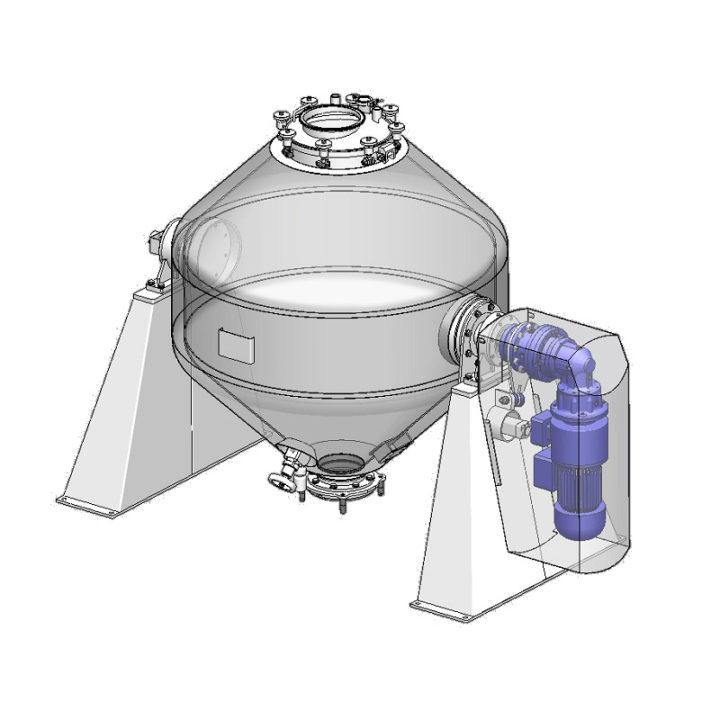

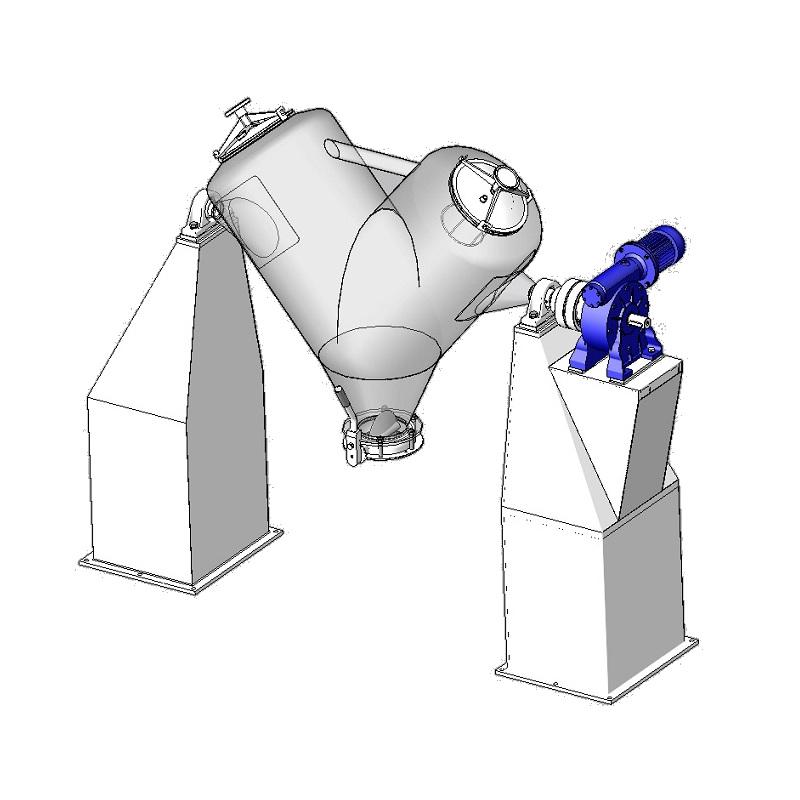

The Double Cone blender with rotary drum for solids and powders is ideal for mixing products with a fragile morphology that must be respected during mixing, or applications with a high cleaning requirement between batch operations.

The Double Cone solid mixer has a biconical drum rotating at low speed, making the product slide gently on its smooth inner walls, performing a non-forced mixing effect.

Advantage

- Repetitive mixings processes, reproducible and easy to scale up.

- Low maintenance required.

- Very easy to clean.

- Complete product discharge.

Features

- Capacities from 100 a 35.000 liters.

- Batch-wise operation.

- Mixing accuracy of 1:10.000 in only few minutes.

- ‘CE’ marking according to the Safety for Machinery Directive 2006/42/CE.

Options

- Internally mirror polishied Ra ≤ 0.6 µm (Grit 360).

- Externally polished in matte or mirror.

- Liquid injection by spraying.

- Heating/cooling jacket.

- Design under pressure and /or vacuum – refer to drying and reactor version.

- Choppers for mixing intensification and lump breaking.

- Product loading through vacuum conveying system.

- Automatic positioning of the machine.

- ATEX executions on request.

- ATEX execution for internal zone 20/0 officially stamped.

- Automatic solids loading and dosing systems.

- Weighting system.

- Formulation installations.

- Product packing system.