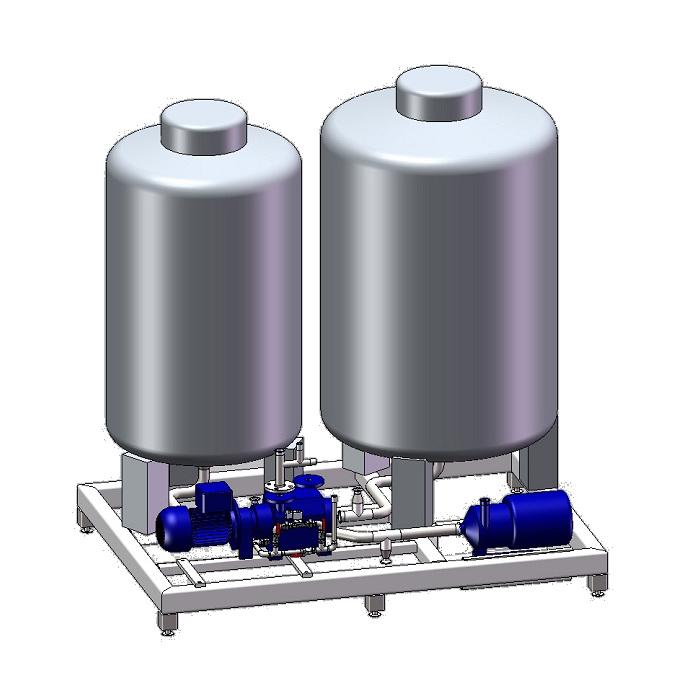

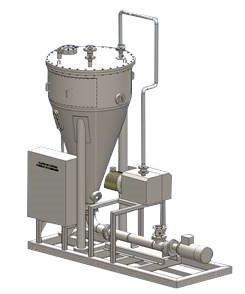

CAPACITIES: from 500L up to 3.000L.

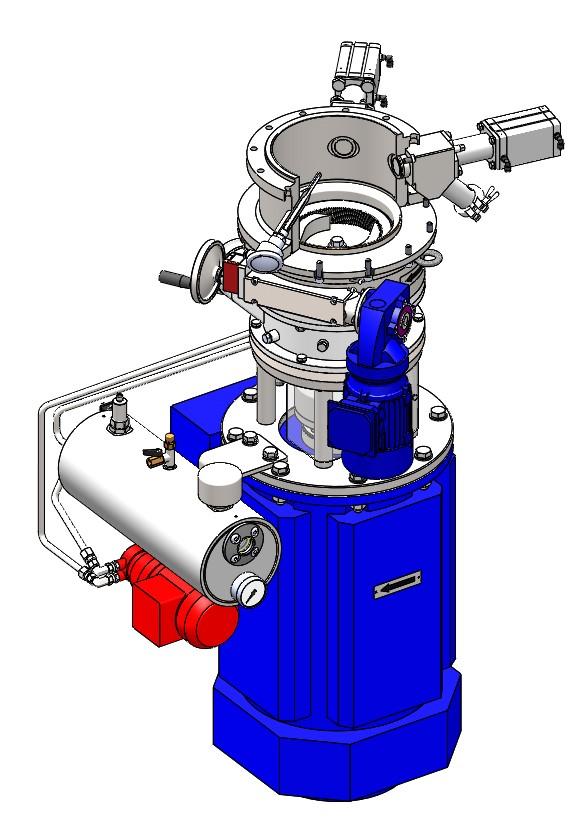

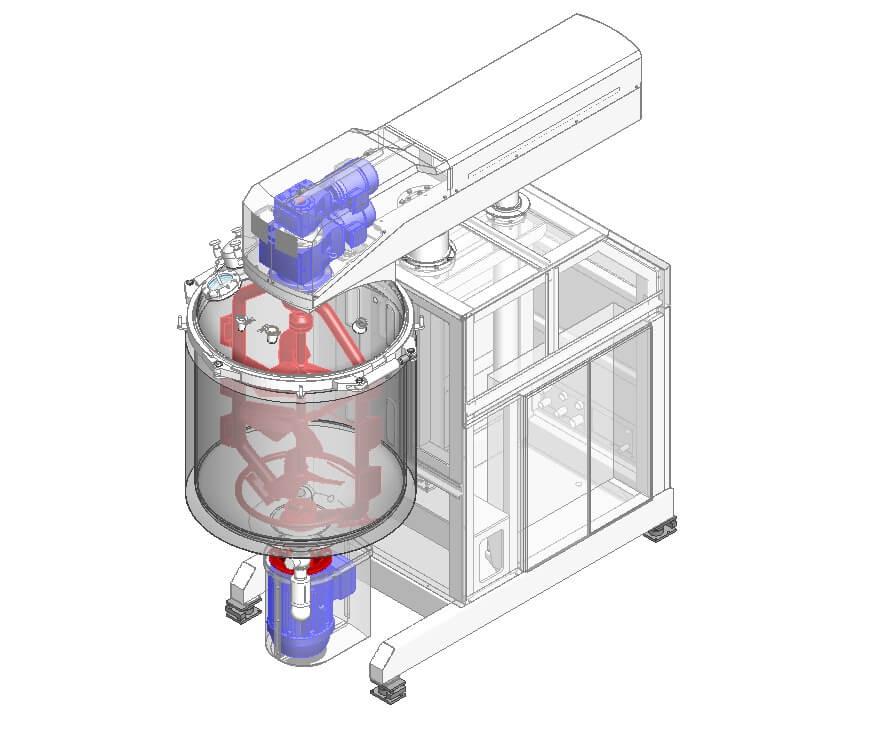

CIP Monobloc cleaning units (Clean in Place) are specially designed for the cleaning of process tanks in the pharmaceutical and cosmetics industries with reduced water loss.

It consists of a cleaning system in stages which rinses with clean water, hot water, reclaimed water, purified water, diluted acid, diluted soda or disinfectant solution, depending on the application.

Advantage

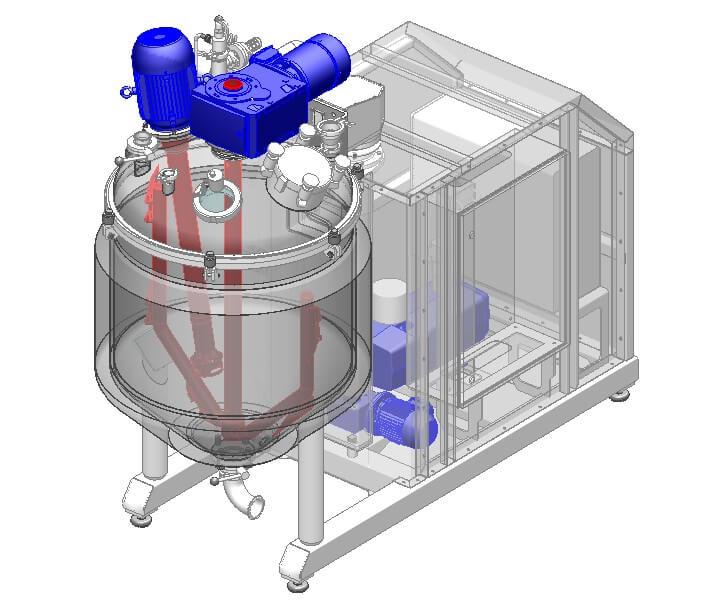

- Monobloc unit in ‘plug and go’ concept.

- Sanitary design according to cGMP.

- Integrated power cabinet.

Features

- Versions with 1, 2 or 3 storage tanks.

- Capacities from 500 up to 3.000 liters.

- Sanitary design according to cGMP.

- Storage tanks heated by means of electrical resistances.

- Sanitary storage tank for purified water.

- Dosing pump for cleaning media.

- Sanitary pump for circulating and washing at a high flow rate.

- Integrated power cabinet.

- Touch screen and control software.

- ‘CE’ markingaccording to the Safety for Machinery Directive 2006/42/CE.

Options

- Validatable FDA version.

- DQ, IQ, OQ protocols.

- CIP (Clean-In-Place) cleaning procedures validatable by Riboflavin test.

- Version for ATEX zone on demand.

- Execution for heating with steam.