ZH-120L Automatic Cartoner Machine Cartoning Machine

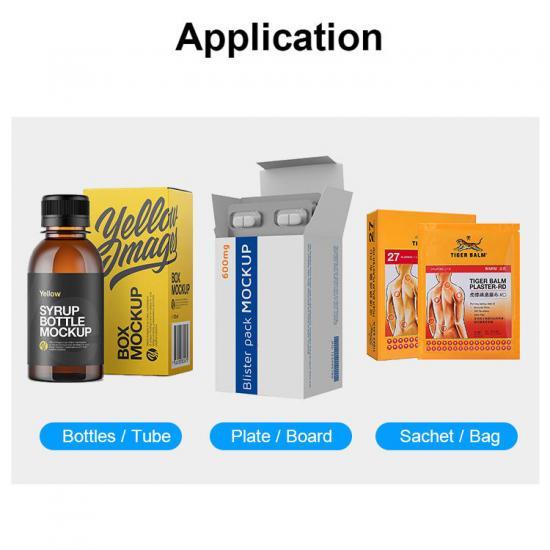

3 Years Warranty | 21 Days Delivery | The feeding progress of the automatic cartoning machine is generally divided into the three entrances: the manual feeding entrance, the medicine bottle feeding entrance and the machine package box entrance. The whole cartoning process from the machine package box feeding to the final packaging molding can be roughly divided into these four stages:

The feeding ways of the automatic box cartoning machine is generally divided into the three entrances: is the manual entrance, the medicine bottle feeding entrance and the machine packing box entrance. The whole carton box packing process from the box carton packing machine feeding to the final packaging molding can be roughly divided into as the four stages:

The carton is fixed by the guide rail and the push plate is used to open the cartons. At the same time, there will be two moves forwards from Raise the bottoms, jam the side of the cartons from the front and the back, open the box at the right angle and finally move it forward to the loading area. After filling in the right filling area, the mechanism of the cartoning machine will fold the carton ears into the left and right guide rails, and then perform the closing actions. The pre-closing mechanism will first bend the tongue of the carton, and then the push plate pushes the lid to the bend, so that the tongues are inserted into the carton and the lock buckle is fastened. The carton closing action is a critical action, and the quality of completion has a lot to do with the structures of the cartons and the accuracy rate of the machine adjustment.

*** Why should choose our's 120L cartoning machine? Regarding the fixed carton production procedure, the production efficiency of the purely manual operation is very low. For example, using the specially developed automatic cartoning machine to pack all kinds of materials bottles, bags, strips and the other products into cartons can increase the effectiveness hundreds of times. It takes at least 30 seconds to rely on operator to pack products. For those products produced by an auto cartoning machine, several cartons can be produced in one second. For example, the vertical models developed and designed by our Rich Packing group can make 25-120 pcs per minute according to the difference in outer packing and the materials. The faster 260W automatic cartoner machine has a maximum output to 260 pieces per minute.

Technical parameter

|

Model |

RQ-ZH-12OL |

|

Speed |

35-125 carton/min |

|

Total power |

1.10 KW |

|

Powersupply |

220/380V 50Hz |

|

Requirements of carton |

size range of carton:L(65-150)*W(35-85)*H(12-45)mm |

|

carton weight:240-360g/㎡ |

|

|

Requirements of instructions |

size range of instructions:L(78-250)*W(85-170)mm |

|

range of folding times of instructions:1-4 fold |

|

|

instructions weight:60-70g/㎡ |

|

|

Pressure |

pressureintensity:≥0.6MPa |

|

air consumption:120-160 L/min |

|

|

Overall size of machine |

2150*1140*1800㎜ |

|

Net weight of machine |

about1500kg |

*** Configuration

|

Item |

Specification |

Qty. |

Manufacturer |

|

Servo motor |

400W MHMD042G1U |

1 |

Panasonic |

|

Servodriver |

400W MBDHT2510E |

1 |

Panasonic |

|

Main motor |

R17DT80N40.75KW/220V/380V |

1 |

GermanySEW |

|

Frequencyconverter |

FC-051P1K5S2E20H |

1 |

Danfoss |

|

Air circuit breaker |

DZ47-D63/2P |

1 |

Yaohua |

|

Air circuit breaker |

DZ47-D63/2P |

3 |

Yaohua |

|

Relay |

MY2NJ/24VDC |

5 |

Japan Omron |

|

Touch screen |

GC—4408W |

1 |

Proface |

|

Switch power supply |

NES-100-24V |

1 |

Taiwan MIWE |

|

Power switch |

T0-2-1/EA/SVB |

1 |

Germany Moeller |

|

PLC |

Smart ST40 |

1 |

Germany Siemens |

|

Fiber amplifier |

E3X-NA11 |

2 |

Japan Omron |

|

Optical fiber |

E32-ZD200 |

2 |

Japan Omron |

|

Encoder |

E6B2-CWZ6C |

1 |

Japan Omron |

|

Proximity switch |

1M12-4NNS |

1 |

Germany SICK |

|

Photoelectric switch |

D-73277 |

2 |

Germany LEUZE |

|

Photoelectric switch |

GTE6-N-1212 |

1 |

Japan Omron |

|

Solenoid valve |

VQ21A1-5G-C8 |

3 |

Japan SMC |

|

Solenoid valve |

VP342R-5GD1-02A |

2 |

Japan SMC |

|

Solenoid valve |

VP542R-5GD1-03A |

5 |

Japan SMC |

|

Solenoid valve |

VQ2321-5G1-02 |

4 |

Japan SMC |

|

Vacuum occur device |

ZH20DS-03-04-04 |

2 |

Japan SMC |

|

Silencer |

AN402-04 |

2 |

Japan SMC |

|

Sucker |

KPS6-WS |

10 |

Korea |

|

Cylinder |

CO20B20-10DC |

3 |

Japan SMC |

|

Pressure switch |

QPM11-N0 |

1 |

AEK |

|

Magnetic switch |

CS1-S |

1 |

AOTAI |

|

Emergency stop button |

ZB2-BE102C |

1 |

France Schneide |