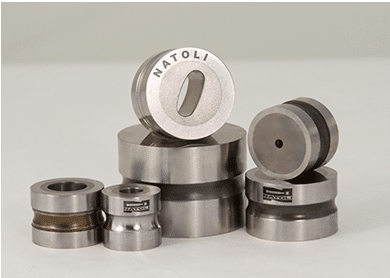

Lined Dies

Wish you could extend your tablet compression tooling life?

Now you can with Natoli’s lined dies…

Our lined dies drastically increase tool life and increase tablet quality.

Lined dies, commonly called insert dies, are used specifically to compress abrasive and corrosive formulation. However, we’ve designed both carbide and ceramic lined dies that will also hold up to significant wear.

What does that mean for you?

- Increased tool life

- Less head wearing

- Reduced friction

- Elimination of corrosion

- Extended tablet quality

Both carbide and ceramic lined dies have an insert that is bonded into an outer steel casing, but each type comes with its own set of benefits.

Carbide Lined Dies

- Recommended with abrasive granulations

- Work well for nutraceutical applications

- Provide a high level of wear resistance during the compression of abrasive products

- Increase die life by more than 10 times due to their wear liner

Our Carbide and Ceramic lined dies are manufactured to the same tolerances and finishes as our standard steel dies. And the steel used for their casing is of the same, trusted quality. This means that our lined dies are made from steel that is: These processes ensure our batch-to-batch consistency always meets what you’ve come to expect from Natoli Engineering.Ceramic Lined Dies

Our lined dies are manufactured for excellent tooling efficiency, durability and performance.